Agitation operations are generally thought of as simple, but they are associated with various operating conditions and purposes. If an incorrect condition or purpose is selected, agitation may be totally impossible. Or, agitation may be possible only at very low efficiency.

To achieve the intended goal, selection of the best agitating blades is important.

Agitating blades vary in shape, as well as in performance.

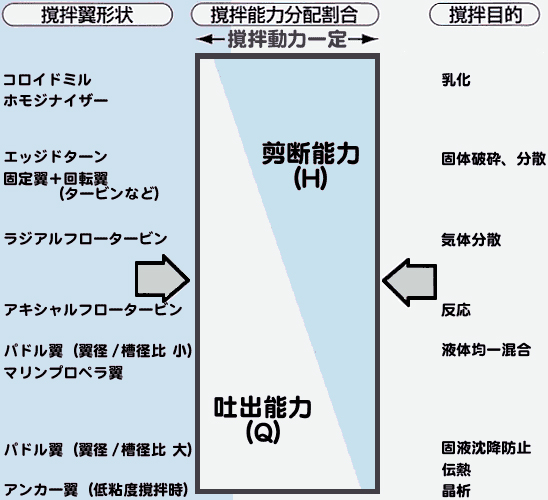

Agitating blades have two actions, discharge action (Q) and shear action (H). The proportion of these two is said to determine the performance. In a given agitation operation, Q or H is required depending on the purpose of the particular agitation. Therefore, selection of the best agitating blades is a process of selecting an agitating blade that provides the best performance (Q or H) required for the given agitation purpose within a certain range of power. In addition, it may be important to scale up the equipment to suit the purpose based on past achievements and experimental results. With Techmix, these consideration points are kept in mind in selecting agitators.

Types of dispute wings commonly used and main scope of application

|

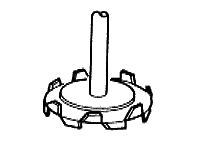

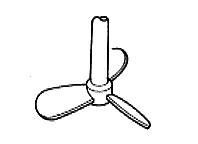

outline of blade figure

|

|

|

|

|

Blade type

|

Edged turbine blade

|

Marine propeller blade

|

|

|

Mainly used

blade diameter / tank diameter ratio |

0.25~0.35

|

0.20~0.30

|

|

|

Mainly used

Number of rotations(rpm) |

500~3000

|

200~400

|

|

|

Mainly used

viscosity range(mPa-s) |

Low to high Max.50000

|

low to middle Max.3000

|

|

|

Main intended use

|

Liquid-liquid system

|

strength dispersion

|

homogenization mixing heat transfer

|

|

Solid-liquid system

|

fragmentation dispersion fusion

|

homogenization Prevent

sedimentation

|

|

|

Gas-liquid system

|

|||

|

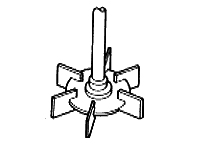

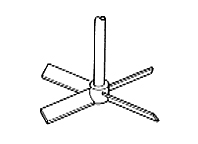

outline of blade figure

|

|

|

|

|

Blade type

|

Turbine blade

|

Paddle blade

|

|

|

Mainly used

blade diameter / tank diameter ratio |

0.25~0.50

|

low-viscosity 0.35-0.50 high-viscosity 0.65-0.90 |

|

|

Mainly used

Number of rotations(rpm) |

50~3000

|

20~100

|

|

|

Mainly used

viscosity range(mPa-s) |

Low to high Max.30000

|

Low to high Max.50000

|

|

|

Main intended use

|

Liquid-liquid system

|

homogenization dispersion behavior

|

homogenization mixing prevention-of-separation

|

|

Solid-liquid system

|

dispersion fusion

|

homogenization Prevent

sedimentation

|

|

|

Gas-liquid system

|

dispersion behavior

|

homogenization behavior

|

|

|

outline of blade figure

|

|

||

|

Blade type

|

Anchor blade

|

||

|

Mainly used

blade diameter / tank diameter ratio |

0.70~0.95

|

||

|

Mainly used

Number of rotations(rpm) |

10~50

|

||

|

Mainly used

viscosity range(mPa-s) |

Low to high (mainly:high) Max. 200,000 to 300,000. |

||

|

Main intended use

|

Liquid-liquid system

|

homogenization mixing heat transfer

|

|

|

Solid-liquid system

|

crystallization homogenization Prevent sedimentation

|

||

|

Gas-liquid system

|

|||

Performance characteristics and agitation purposes of various agitating blades

Our Production Division will make a selection and quote an estimate for the agitator you wish.

Please print the Agitator Estimate Sheet, fill out necessary information, and fax the completed sheet.