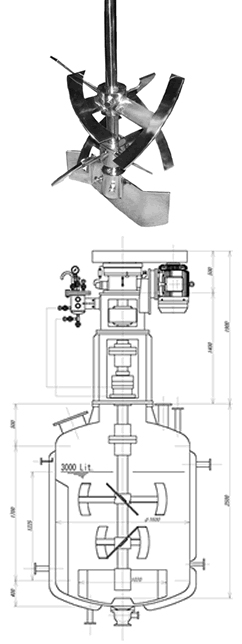

ORIGINAL MULTIPURPOSE AGITATOR

FFM (Full Fine Mixing) Agitator

The FFM agitators have been developed as multi-purpose agitating machines that operate in a wide range of viscosity,

from low to high levels, for liquid-liquid, liquid-vapor, and liquid-solid conditions.

Features

- Available in broad areas of viscosity, from low to high (up to 300,000 to 500,000 mPa).

- A single blade serves multiple purposes while balancing two major agitation actions: circulation and shearing.

- Mixing and dissolution times can be reduced as compared with conventional agitating blades. (For example, resin dissolution completes in two-thirds the time it takes with an existing machine.)

- The unique shape and arrangement of blades are best suited also for agitation with specific gravity difference and viscosity difference.

- Superior cost performance to large blades from other companies.

Applications

- Dissolution and mixing of rubber, resin, paint, ink, etc.

- Mixing of high-concentration slurry.

- Mixing of low-liquidity fluids.

- Agitation of high sedimentary liquid-solid system.

- Liquid-liquid system: Mixing, reaction, emulsification, dispersion, etc.

- Liquid-solid system: Dissolution, reaction, suspension, dispersion, etc.

- Liquid-vapor system: Mixing, reaction, dispersion, etc.

Available for your use are 50-L and 150-L test machines. Please feel free to contact our sales staff.

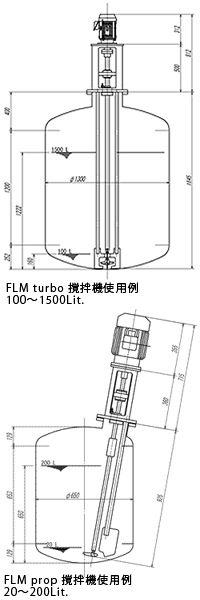

FLM (Full Level Mixing) Agitator

Developed to maintain satisfactory agitation conditions at all liquid levels, from full to low levels.

Features

- The minimum liquid level available for agitation corresponds to 1/10th to 1/20th of full level.

- No need to install a baffle in the agitating tank.

- The flow form in the tank is primarily vertical circulation flow, which is effective for agitation.

- Almost no entrapment of air bubbles.

- Absence of speed reducers means low noise and cost.

FLM agitators come in two types: FLM-prop for small capacities (approx. 200 L or lower) and FLM-turbo for large capacities.

Applications

- Ideal for liquid-liquid and liquid-solid mixing and dissolution, for chemical solutions, medical drugs, lotions, perfumes, dyes, etc.

- For tanks incapable of installing a baffle.

- For fluids that should not entrap air bubbles.

- Strict noise regulation precludes use of a speed reducer.